GoTEE

Production, Efficiency, Attendance & Maintenance in a single box.

GoTEE (Production Monitoring System)

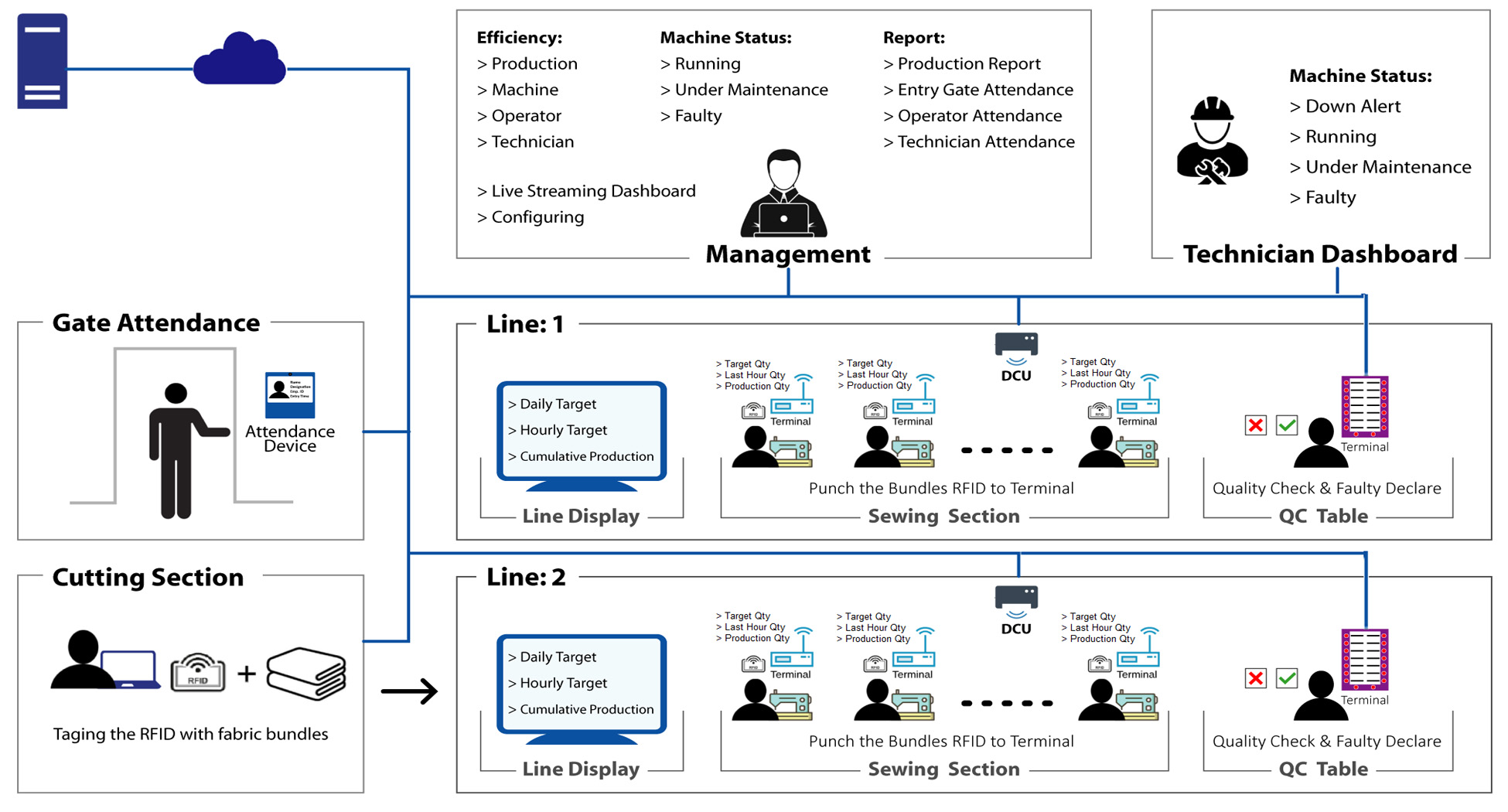

GoTEE is our individual efficiency and production monitoring System in the garments shop floor. True attendance, machine maintenance are packed with the solution as well.

GoTEE will help you monitor your floor production in Realtime from anywhere using the cloud server. Users will be able to always keep track on the delivery schedule and production value. The solution will also give detailed analysis of floor, line, style, color, buyer etc.

GoTEE enables user to have true attendance of the workers from the working table. The attendance at the gate can be compared with workstation working hour to detect working time losses in a factory with thousands of worker without any issue.

with GoTEE operators can declare different machine faults, production faults. Technician dashboard and technician acknowledgement allows user to have ultimate control over the faults, cause, restoration time as well as technician performance and machine performance.

Finally GoTEE helps to detect individual worker efficiency in a line environment. finding the slow worker can help identify the issues and upgrade the individual. Also the skilled/efficient workers can be given incentives to encourage others which will eventually increase the overall efficiency and profit.

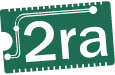

Tagging Device Operation

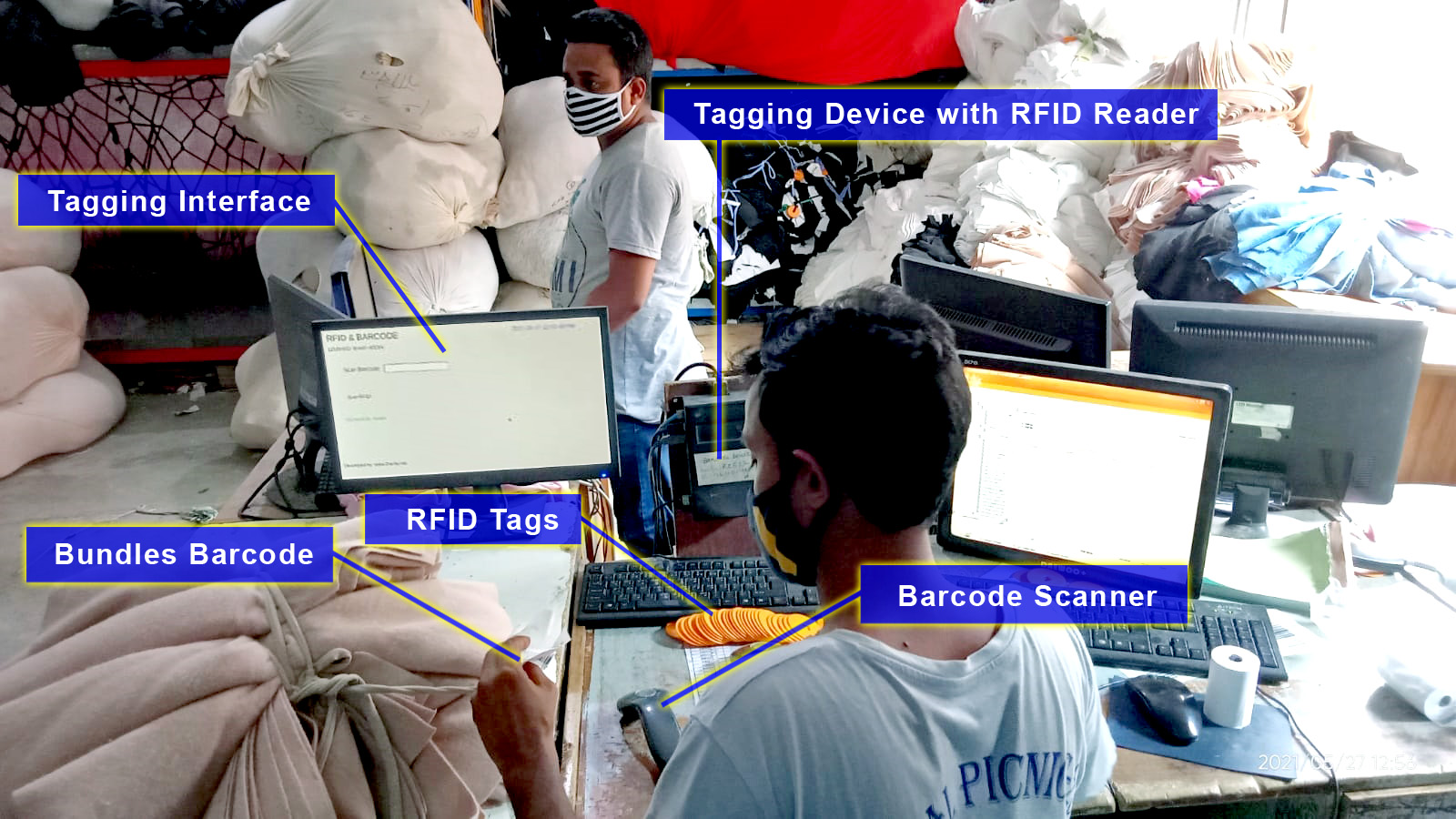

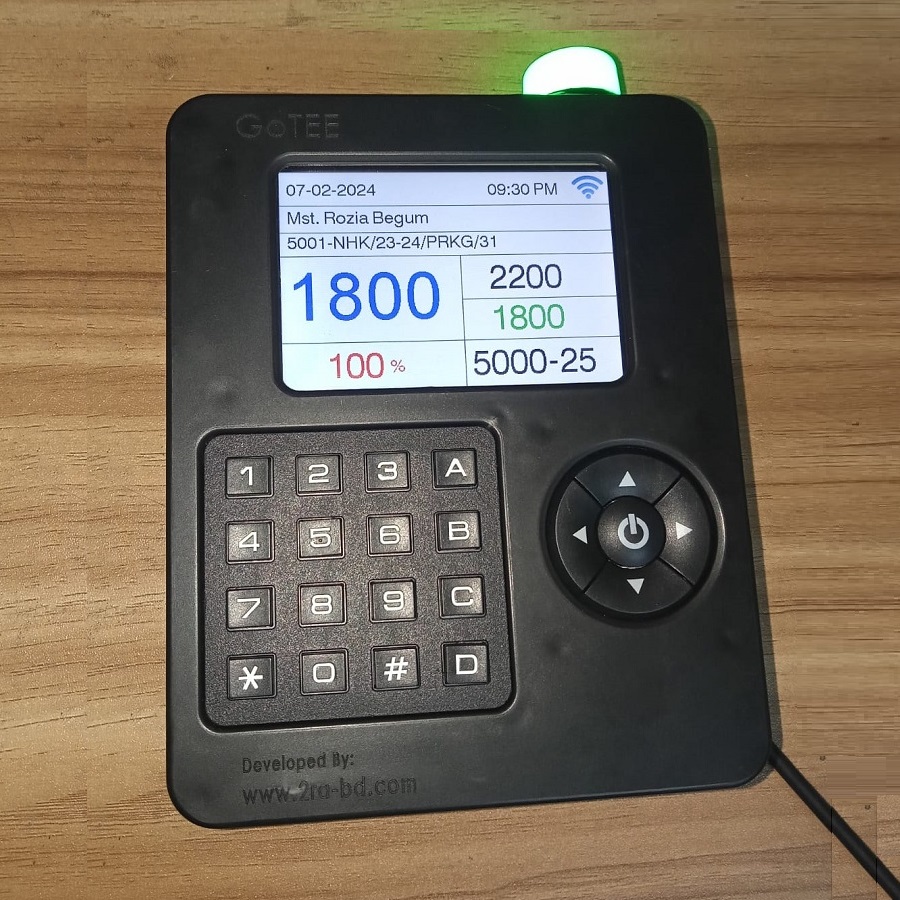

Terminal Device Operation

QC Device Operation

GoTEE System Diagram

GoTEE Device & System Component

Terminal 4.0

- 3.5″ Graphic (Full color) LCD 480×320 px

- 16 Key keypad for input & 5 Way navigation buttons

- RFID card reader interface

- WiFi Communication interface (2.4 GHz)

- Operator Attendance scan, Production tag scan, Technician attendance scan

- Fault calling. LED status indicator (Green- Normal, RED- Machine fault, Blue- Quality fault)

- Roaming QC input, Supervisor Input, Finishing Line QC input, HR Performance input

- Operation number, Order number entry

- Will show order number, Operation number, Operator name, Operator efficiency, Daily production target, Running total target, Operation qty achieved in display.

- Etc.

Software

- Login with Authentication.

- Live Streaming Dashboard

- Master Dashboard: Current days Sewing & QC Production, Alter & Reject, Employee Attendance & Machine Running, Best Worker & Technician.

- Hourly Sewing Production Dashboard.

- Employee, Operation & Machine wise Current Production Dashboard

- Report:

- Efficiency: Employee, Production, Machine & Technician

- QC Pass/Fault Details.

- RFID Tag Inventory Report

- Configuration & Operation Interface:

- Line Layout Interface.

- Data Synchronization Interface (Machine, Employee, Line List, Fault List)

- Device Configuration & Maintenance

- Database with MSSQL, MySQL.

Start Project with Us!

Our Valued GoTEE Users:

- H.R. Textile Mills Ltd (Pride Group)

- Jinnat Apparels Ltd (DBL Group)